C15/P15 Quench Glands

An oil quench gland is a specialized accessory used in mechanically sealed pumps, primarily in industries such as pulp and paper, where the protection of the pumped fluid is essential. This unique quench gland plays a critical role in providing a barrier between the fluid being pumped and the external environment, maintaining the integrity of the pump system and safeguarding the process fluid against contamination. This is particularly vital in applications where the pumped fluid is highly sensitive to the external atmosphere, such as certain starches that can crystallize upon exposure to air.

Here is an in-depth look at the oil quench gland for mechanically sealed pumps:

Purpose: The primary purpose of an oil quench gland is to provide a protective barrier to the mechanical seal. It prevents any contamination or dilution of the process fluid, thereby avoiding premature wear of the seal due to crystallization of the fluid on the seal faces. In the pulp and paper industry, this is of utmost importance due to the corrosive and abrasive nature of the fluids involved. The oil quench gland serves several key functions:

- Contamination Prevention: It acts as a barrier, ensuring that no external substances, such as pulp residues or process chemicals, can infiltrate the seal chamber. This is essential for maintaining the purity and quality of the process fluid.

- Lubrication: The oil used in the quench gland serves as a lubricant for the mechanical seal components. It reduces friction and wear on the seal faces, significantly extending their operational lifespan.

- Cooling: In situations where the process fluid generates heat, the oil quench gland assists in dissipating this heat, preventing overheating of the seal faces.

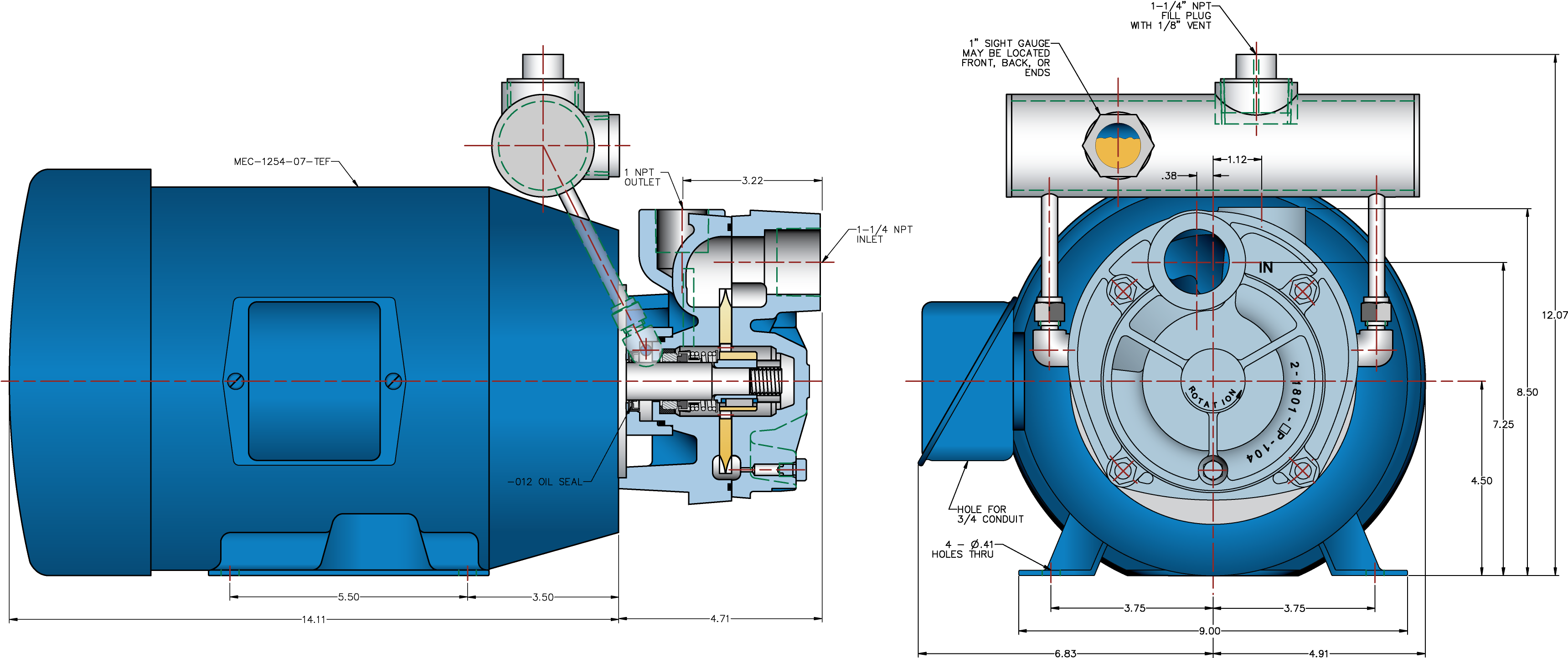

Components: An oil quench gland for a mechanically sealed pump comprises several essential components:

- Oil Reservoir Tank: Located atop the gland housing, and above the motor and/or bearing pedestal, the oil reservoir tank is constructed with stainless-steel components to resist corrosion and remain compatible with both the process fluid and the quenching oil. Its purpose is to ensure a continuous and adequate supply of oil to protect the mechanical seal.

- Oil Site Glass: The quench gland is equipped with a sight glass facing the front of the pump, allowing for easy monitoring of the condition and levels of the quenching oil through a glass window.

- Distribution System: The oil quench gland incorporates a distribution system that uniformly delivers the quenching oil to the back of the mechanical seal seat, typically from behind the motor bracket of the pump. This ensures consistent lubrication and cooling.

Operation: During operation, the oil quench gland is supplied with quenching oil. This oil flows behind the seal seat, creating a protective barrier around the mechanical seal. It serves as a lubricant, cooling agent, and contaminant blocker, safeguarding the seal faces and preventing premature seal wear.

Applications: Oil quench glands are essential in industries where the purity and integrity of the process fluid are critical, such as the pulp and paper industry. They are used in pumps that handle corrosive, abrasive, or chemically reactive fluids to ensure the reliability and longevity of mechanical seals.

In conclusion, an oil quench gland is a specialized accessory designed to protect the process fluid in mechanically sealed pumps, especially in industries like pulp and paper, where fluid purity is paramount. The MTH Seal Quench Gland is available on all T41 and T51, C15 (Close Coupled Pump and Motor) and P15 (Pedestal mounted pumps) configurations.