Filter Back Flush

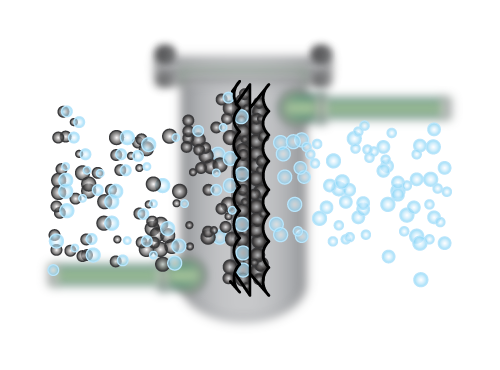

In many industrial and environmental processes, maintaining fluid cleanliness is crucial, and filters are commonly employed to ensure this. However, over time, these filters can become clogged with contaminants, necessitating a method to restore their efficiency. One effective solution is a back flushing system, which uses high-pressure jets to dislodge and flush out the accumulated debris, thus extending the life of the filters and maintaining system performance.

In particular, regenerative turbine pumps are exceptionally well-suited for filter back flush applications due to their ability to deliver high-pressure flows consistently. A practical example of this can be seen in groundwater remediation systems, where layered filter trays with small holes are used to remove contaminants from the water. As water cascades through these trays, contaminants get trapped, but over time, these holes can become obstructed by a heavy buildup of debris.

To address this issue, an automatic back flush system is employed. This system utilizes MTH regenerative turbine pumps to generate the high pressure necessary—around 300 psi—to force contaminants out of the filter holes. The robust design of these pumps ensures that they can handle the high pressure and flow rates required for effective back flushing, thereby cleaning the trays and ensuring the continuous operation of the system.

By incorporating regenerative turbine pumps into your filter back flush system, you can achieve efficient and reliable cleaning of filter media, which in turn enhances the overall performance and longevity of your filtration system. For detailed guidance on selecting and sizing the right pump for your specific application, please visit our standard products page.